|

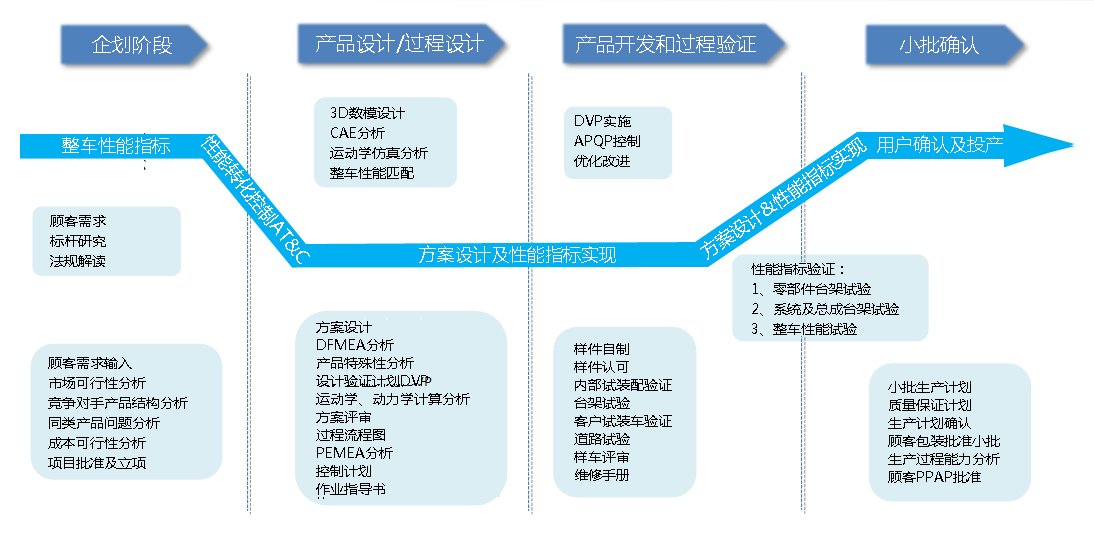

| Shanghai Komman always adheres to the customer demand-oriented, with the design and development concept of "technical Koman, making driving and riding more comfortable", to provide customers with the best air suspension solutions. The product realization of Koman suspension system is divided into four stages: planning stage, product design & process design, product development and process verification, and small batch confirmation. In the planning stage, it takes the customer's overall performance index requirements as the basic input, carries out feasibility analysis (market, cost, structure, technology, etc.) of each index demand, benchmarking, and establishing the scheme development plan. Product design & process design is the realization of project requirements, including system structure scheme design and process design. The structure design mainly includes system scheme layout, parts design, vehicle performance index matching, DFMEA analysis, etc.; product development and process verification mainly include bench test and sample vehicle road test certificate of suspension system. After the bench test and road test are passed, they will be submitted to the customer PPAP, and the application will be transferred to a small batch. |

|